Bronze Bearing Idler Sprockets

As one of the idler sprocket manufacturers, suppliers, and exporters of mechanical products, We offer idler sprockets and many other products.

Please get in touch with us for details.

Mail:[email protected]

Manufacturer supplier exporter of idler sprockets.

Bronze Bearing Idler Sprockets

An idler sprocket is a critical component in conveyor systems, responsible for maintaining tension in the chain and guiding it around bends and corners. It plays a crucial role in ensuring the smooth and efficient operation of the conveyor system.

Idler sprockets are designed to work with conveyor chains, which are used to move materials from one location to another. They are typically made from high-quality materials, such as steel or cast iron, and are highly resistant to wear and tear. Idler sprockets come in a variety of sizes and tooth configurations, depending on the specific application.

Bronze bushing idler sprockets are very durable. Bronze is used because it is self-lubricating, economical, and easy to press into the sprocket. Our bronze bushing sprockets are manufactured using high quality bronze with high strength heat treated sprockets.

Idler Sprockets Parameter:

- Durable & High Performance Sprocket

- Uses High Quality Needle Bearing

- Fully Meets All ANSI Standards

- Has Hardened Teeth

| Sprocket Size | Number Of Teeth | Bearing Type | Chain Size | Outside Diameter | Bore Size | Length Thru Bore | Dimension (T) | Hub Diameter | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 35BR15 | 15 | Bronze Bearing | #35 | 1.99″ | 1/2″ | 0.94″ | 0.168″ | 1.35″ | 0.30 LBS |

| 35BR21 | 21 | Bronze Bearing | #35 | 2.71″ | 7/8″ | 1.06″ | 0.168″ | 2.00″ | 0.75 LBS |

| 40BR13 | 13 | Bronze Bearing | #40 | 2.33″ | 1/2″ | 0.94″ | 0.284″ | 1.56″ | 0.50 LBS |

| 40BR19 | 19 | Bronze Bearing | #40 | 3.29″ | 7/8″ | 1.06″ | 0.284″ | 2.50″ | 1.25 LBS |

| 41BR13 | 13 | Bronze Bearing | #41 | 2.33″ | 1/2″ | 0.94″ | 0.227″ | 1.56″ | 0.50 LBS |

| 41BR19 | 19 | Bronze Bearing | #41 | 3.29″ | 7/8″ | 1.06″ | 0.227″ | 2.50″ | 1.00 LBS |

| 50BR13 | 13 | Bronze Bearing | #50 | 2.91″ | 1/2″ | 0.94″ | 0.343″ | 1.87″ | 0.90 LBS |

| 50BR17 | 17 | Bronze Bearing | #50 | 3.72″ | 7/8″ | 1.06″ | 0.343″ | 2.62″ | 1.50 LBS |

Maintenance Of Idler Sprocket:

To ensure that idler sprockets continue to perform optimally, regular maintenance is necessary. The sprockets should be inspected on a regular basis for signs of wear and tear, such as chipping, cracking, or excessive wear on the teeth. If any of these signs are present, the sprocket should be replaced immediately. Additionally, regular lubrication is necessary to reduce friction and prevent premature wear.

We are one of the best idler sprocket manufacturers.We can offer wide idler sprocket stock and corresponding chain.We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us!

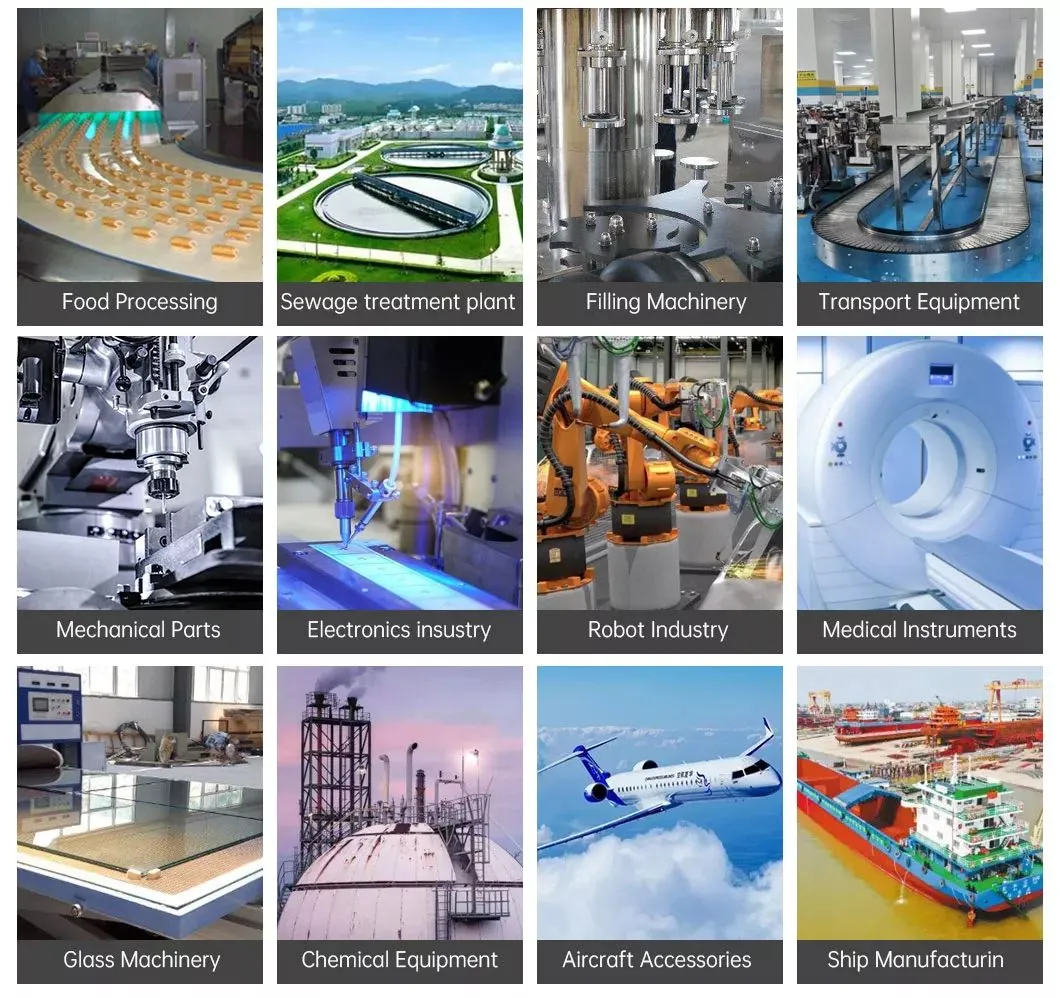

Idler Sprocket Application: